Improve

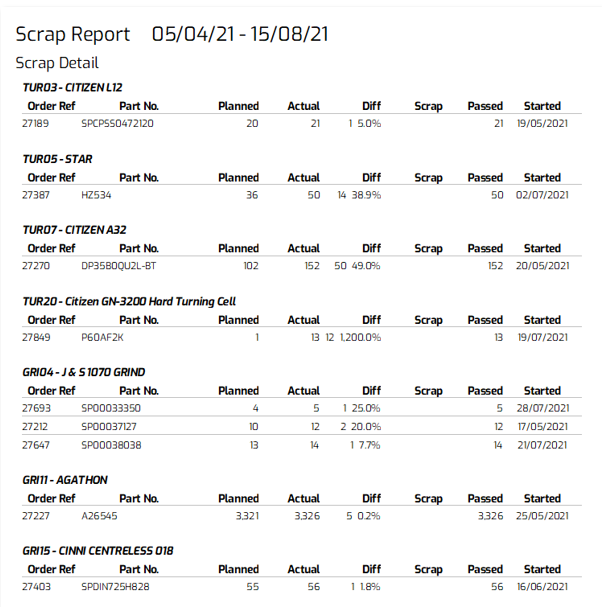

By analysing production time, downtime, machine activity time, quantity produced and scrappage, FactoryIQ provides dashboards and reports to help identify exceptions and trends, and guide the improvement process.

Valuable metrics including OEE and OTIF are automatically calculated in real time enabling you to intervene faster.

All data is held in perpetuity, so the pace of improvement can be easily determined. Resources can be planned and jobs costed more accurately based on this historical data.

With accurate data available you can start to confidently make decisions about future investments, for example identifying a previously invisible "pinch point" in your processes could justify the purchase of a new machine. Likewise, you might find spare capacity in some areas which your sales team can take advantage of.

FactoryIQ features a wide variety of standard management reports. We can also build bespoke reports to produce analyses specifc to your organisation.

Data from EdgeMonitors can drive improvement through better use of resources. As the saying goes "if the spindle's not turning, the machine's not earning". Seeing patterns of idle time on machines will enable you to better plan staffing and workload, and identify areas of poor performance, e.g. extended changeover times.

In a world of spiralling energy prices, environmental awareness and the requirement to reach Net Zero there is a pressing need to improve energy efficiency. Updates to our EdgeMonitors are currently under development that will allow you to sub-meter power usage throughout your factory, allowing you to quickly identify areas of excessive energy consumption and wastage.