Machine Monitoring Made Simple

Machine monitoring needn’t be complex or expensive. Our FactoryIQ Edge device can be installed on virtually any machine in minutes, sending data to our cloud service so you can monitor activity and trends anytime, anywhere

FactoryIQ EdgeEssentials: Machine Monitoring Simplified

Discover the power of data-driven insights with FactoryIQ EdgeEssentials. Our intuitive machine monitoring solution can be installed on virtually any machine, offering you real-time performance trends anytime, anywhere. Machine monitoring needn’t be complex or expensive.

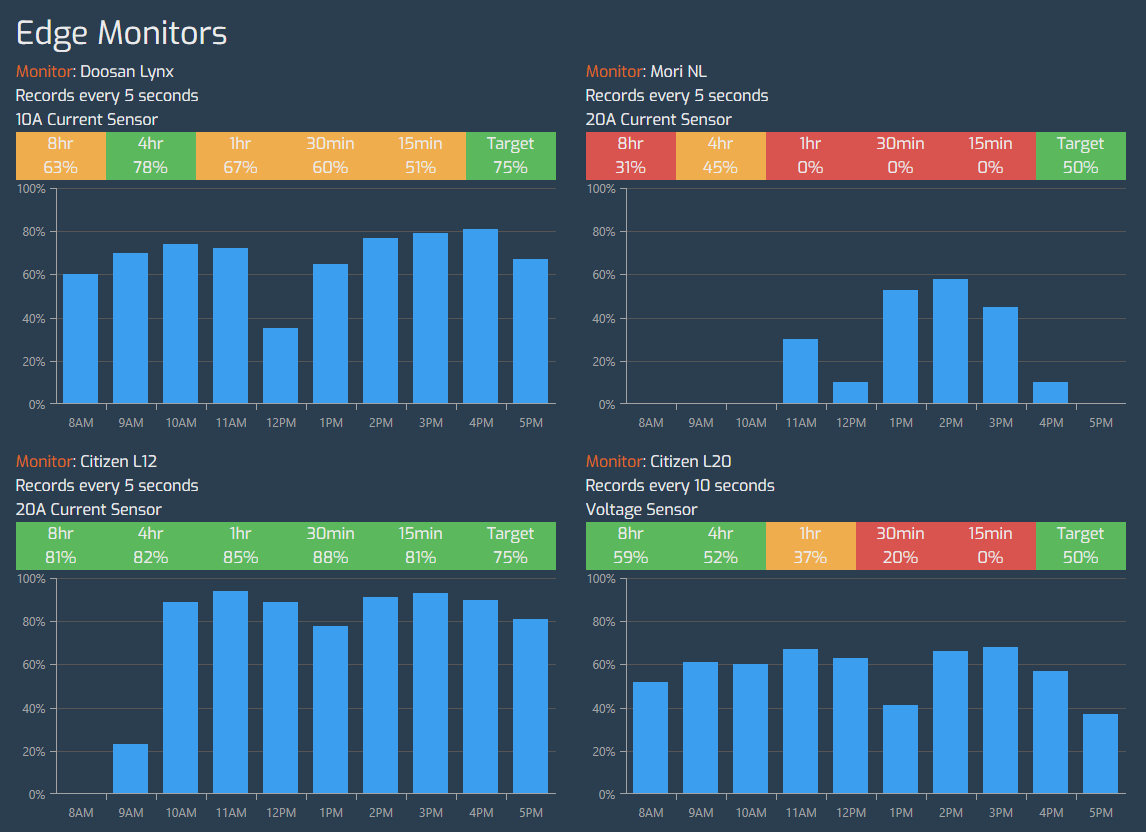

Real-Time Machine Monitoring

Keep an eye on your assets with FactoryIQ - EdgeEssentials. Monitor machine activity in real-time, making it easy to identify trends, issues, and opportunities to boost productivity.

Revolutionising Energy Efficiency in Manufacturing

Given the accelerated journey towards Net Zero, SME Manufacturers are pivoting towards sustainable and efficient operations. Efficient energy consumption is critical, and real-time energy monitoring is the centre stage. FactoryIQ's EdgeEssentials is here to revolutionise energy efficiency in manufacturing!

An ultra low-cost entry into digital manufacturing, EdgeEssentials unfolds machine productivity, revealing trends, issues, and unseen opportunities to manage and optimise your energy efficiency. Harness energy data from your assets accurately, affordably, and effortlessly, making a significant stride towards your sustainable goals.

Historical Data Analysis

Dive deep into your machines' performance history. Understand how your assets have been utilised over time, and make informed decisions based on historical data.

Browser-Based Dashboard

Easily compare machine performance and activity across cells and time periods with our browser-based dashboard. Receive automated email alerts when certain thresholds are met, ensuring a proactive approach to machine maintenance.

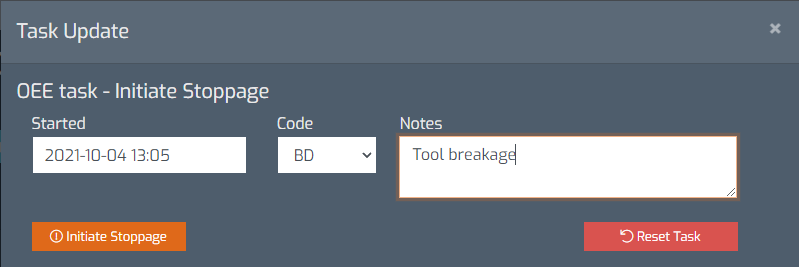

Downtime Reason Logging

Empower operators to record the reason for downtime using a tablet. This valuable information facilitates root cause analysis and helps prevent future issues.

Easy Installation & Upgrade Path

Install our EdgeMonitor devices in just a few minutes and watch as they begin recording machine utilisation data in real-time. When you're ready to take your operations to the next level, easily upgrade to the full FactoryIQ suite for Scheduling, OEE, Document Management, and more.

Don't Let Productivity Stay Hidden

Uncover the hidden potential of your factory with FactoryIQ EdgeEssentials. Get in touch with us to schedule a free demo and see for yourself how our solution can transform your manufacturing processes.

plus one-off cost of £175 per machine for hardware

Knowing the actual utilisation of your assets could be the single most important metric in your business. Recognising this, we have introduced FactoryIQ EdgeEssentials providing an ultra low cost entry into digital manufacturing. Featuring FactoryIQ’s core machine monitoring functionality, EdgeEssentials gives both a realtime view of machine activity, as well as a historical timeline, enabling you to identify trends, issues and opportunities to boost productivity. When the time is right, you can easily upgrade to the full FactoryIQ suite, giving you Scheduling, OEE, Document Management and much more

Peter Boneham – Managing Director