Blog

The Power of Red, Amber, Green

28th November 2025Transform your production meetings with the powerful Red, Amber, Green system. Learn how this simple visual method helps you instantly spot problems, focus discussions, and solve issues faster.

READ MORE

5 Signs Your Factory is Leaking Money Through Unplanned Downtime

7th November 2025Is unplanned downtime killing your factory's profits? Learn the 5 silent signs, from constant firefighting to recurring breakdowns, and discover how to stop the financial bleed for good.

READ MORE

The Hidden Factory Stealing Your Profits: How Micro-Stoppages Are Costing You Money

25th September 2025Is an invisible "Hidden Factory" of waste secretly draining your profits? Learn how small, recurring stops, rework, and slowdowns can consume up to 40% of your manufacturing capacity & how to fix it.

READ MORE

Calculating the Real ROI of a Production Scheduling System (A Step-by-Step Guide)

10th September 2025What's the real ROI of a production scheduling system? Our guide provides the formulas & steps to calculate your financial gains in throughput, labour, and scrap to build a bulletproof business case.

READ MORE

5 Signs Your Excel Schedule is Killing Your Profitability

15th August 2025Is your factory's Excel schedule causing more harm than good? Discover 5 signs it's secretly killing your profits, from daily firefighting to unreliable delivery dates. It's time to regain control.

READ MORE

The Single Source of Truth: Why Scattered Systems Are Sabotaging Your Success (And What to Do About It)

31st July 2025You know the drill. Production is humming along, deadlines loom, and then suddenly the paperwork fairy vanishes. Training records are misplaced, versions of Standard Operating Procedures don’t match, and quality checks get lost in a tangle of spreadsheets or sticky notes. It’s frustrating, it’s stressful, and honestly, it’s all too common on factory floors across the UK.

READ MORE

The Silent Profit Killer: How UK Manufacturers Can Win the War on Downtime

20th May 2025Boost machine uptime and efficiency in UK manufacturing with practical tips on maintenance, IoT, metrics tracking, and more. Learn how measurement drives improvement and reduces costly downtime. Optimise your factory today!

READ MORE

Preparing for the Future: Upskilling the Manufacturing Workforce

10th April 2025The manufacturing industry is undergoing a rapid transformation, driven by advancements in automation, IoT, and data analytics. While these innovations improve efficiency and productivity, they also bring a critical challenge: ensuring the workforce is equipped with the necessary skills to operate, manage, and optimise these technologies.

READ MORE

The Smart Factory Secret Weapon: Why UK Manufacturers Are Falling in Love with FactoryIQ MES

14th February 2025Discover how a Manufacturing Execution System can revolutionise your factory. Boost efficiency, quality, and profitability with real-time data, streamlined processes, and empowered workers. Stay competitive in UK manufacturing.

READ MORE

Navigating Rising Labour Costs: How Digital Manufacturing Software Can Help UK Manufacturers Thrive Post-2024 Budget

18th December 2024 (updated March 2025)Discover how UK manufacturers can combat rising labour costs post-2024 Budget with digital manufacturing software. Learn to optimise operations, boost efficiency, and thrive in a challenging economic landscape.

READ MORE

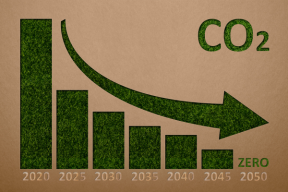

The Carbon Crucible: How UK's Green Tax is Forging a New Reality for Small Manufacturers

28th August 2024The UK's Carbon Border Tax poses challenges for small manufacturers like higher costs & supply chain disruptions, but offers opportunities to innovate, go green and gain an edge.

READ MORE

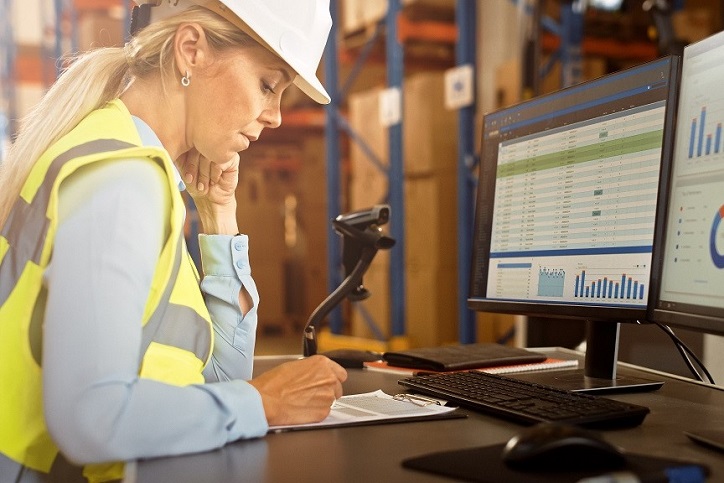

Unlocking the Secrets of Machine Efficiency

20th June 2024Real-time machine monitoring boosts UK manufacturing. It enhances efficiency, minimises downtime, and optimises production. Discover its benefits.

READ MORE

Maximising Machine Uptime: Real-Time Monitoring

22nd April 2024In the competitive landscape of modern manufacturing, maximising machine uptime is not just an operational goal—it's a strategic imperative. Every moment of downtime equates to lost productivity and, ultimately, lost revenue.

READ MORE

Navigating Employee Concerns with Machine Monitoring

28th February 2024Machine monitoring has emerged as a vital tool for businesses seeking optimisation. However, concerns about privacy, job security, and a perceived lack of trust can create a rift between the benefits of technology and the human element of its application.

READ MORE

How SME Manufacturers Play a Role in Reducing Scope 3 Emissions

14th December 2023The UK's plan to become net-zero by 2050 is an ambitious goal that demands collaborative efforts across all sectors. One such key area of focus is Scope 3 emissions - a significant yet often overlooked component of a company's carbon footprint

READ MORE

Navigating the Path to Net Zero

15th November 2023In today's world, sustainability has become more than just a buzzword; it's a necessity. The manufacturing sector is now stepping up to the plate with innovative solutions to reduce emissions and minimise its carbon footprint

READ MORE

Enhancing Energy Efficiency with IIoT and MES

28th September 2023Global manufacturing is fast becoming an arena where energy efficiency is a crucial player. Optimisation of energy consumption has transformed from a competitive advantage into an absolute necessity

READ MORE

The Importance of Effective Production Planning

11th July 2023The image is all too familiar - the bustling factory with roaring machines, hurried workers wavering between piles of unfulfilled orders, and an ever-increasing sense of disorder and confusion

READ MORE

The Journey to Digital Manufacturing

16th May 2023Manufacturers are increasingly looking to manufacturing execution software (MES) for real-time information, increased efficiency and reduced costs. The primary driver behind this trend is the growing demand for speed in the supply chain

READ MORE

The Benefits of a Modern Production Planning System for Manufacturers

2nd March 2023A modern production planning system is an essential tool for manufacturers. This type of software helps you to plan and coordinate the manufacturing process, from ordering raw materials to scheduling your manpower

READ MORE

How MES makes Life Easier and Simpler

3rd February 2023MES is a computer-based technology that improves manufacturing productivity and quality. An MES can provide a single view of the entire production process, including real-time monitoring and control as well as historical data analysis.

READ MORE

Organise All Your Factory Operations In One Place

26th January 2023Adam Payne, Co-Founder of Factory IQ and a manufacturing consultant with 25+ years working in operations, explains why he and Peter Spiby of 4C Software built a new software platform to assist operations managers to bring structure to the ball juggling.

READ MORE

What is Manufacturing Execution Software?

7th December 2022Manufacturing Execution Systems (MES) software, or Manufacturing Operations Management (MOM) software, is designed to manage, track and improve the flow of information and resources between manufacturing facilities and all other business processes.

READ MORE

What is Overall Equipment Effectiveness (OEE)?

20th October 2022OEE is a measure of the efficiency and productivity of a manufacturing operation. It is a powerful tool that can help companies identify areas of improvement and increase their bottom line. This blog reveals the benefits of OEE.

READ MORE