Machine Monitoring Software

Achieve More Without Big Budgets or Big Disruption: Reveal Inefficiencies You’ve Never Seen Before and Give Your Team the Power to Drive Performance Every Single Shift

It’s 3:15 PM on a Tuesday. The silence is the first clue.

Dave, the production manager, looks up from his desk. But today, the steady rhythm of production had gone quiet. Again. He grabs his clipboard and begins the long walk across the concrete floor, a walk he knows all too well.

By the time he gets to the CNC machine, he gets three different stories. The operator says the machine just stopped. The team lead thinks it’s a tooling issue. The job sheet, filled out an hour ago, says everything is running perfectly. Three people, three stories, and one very expensive machine sitting idle while a critical order gets closer and closer to being late.

Dave’s gut tells him this happens too often. But gut feelings don’t show up on a spreadsheet.

This little scene, or something a lot like it, plays out in factories every single day. The core problem isn't just a machine stoppage. It's the not knowing. It's managing by walking around, relying on second hand information, and trying to piece together the truth from a mess of paperwork and opinions.

What if you knew the truth, instantly, without ever leaving your desk?

The End of Walking the Floor for Answers

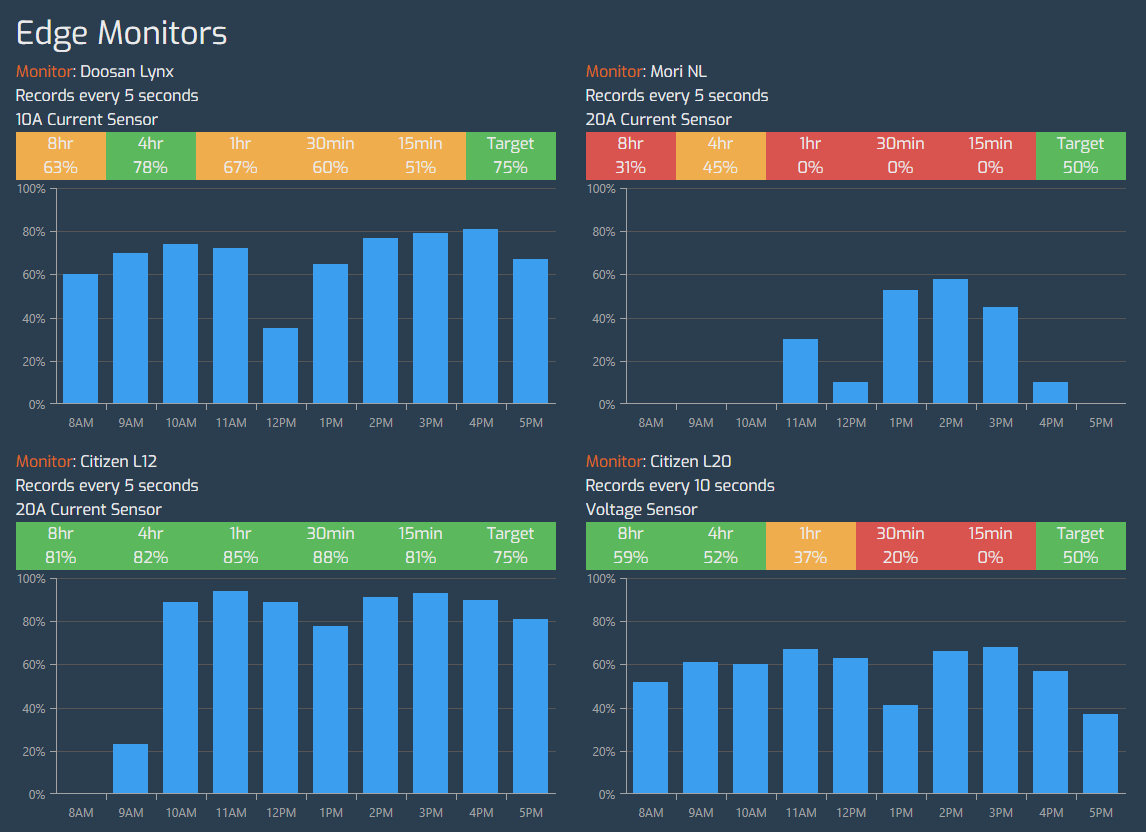

Imagine having a single screen that gives you a god's eye view of the entire factory.

You see the status of every single job, on every single machine, in real time. Green for on track. Amber for falling behind. Red for stopped. Simple.

You see bottlenecks forming before they become disasters. You know instantly if you're on track to hit your numbers for the shift. You can finally stop managing by gut feeling and start making decisions with actual, undeniable facts.

This isn't just data. It's control. It’s the confidence of knowing exactly what’s going on, everywhere, all at once. It’s the peace of mind that comes from catching problems in minutes, not hours. Honestly, it's the feeling of being ahead of the game, not constantly trying to catch up.

Your First Step to a Smarter Factory is Surprisingly Simple

We know what you're thinking. "Digital manufacturing" sounds expensive, complicated, and like a massive headache to install.

We thought about that, too. That's why we created FactoryIQ EdgeEssentials.

For just £75 per month per machine, plus a one off hardware cost of £175, you get the single most important metric in your business: the truth about what your machines are actually doing.

It’s the ultra low cost entry into digital manufacturing you thought didn't exist.

Your smartest competitors are already using data to win bigger contracts and run leaner operations. EdgeEssentials is the simplest, fastest way to stop guessing and start competing, without the massive upfront investment you're dreading.

You get a real time view of machine activity and a historical timeline, so you can finally spot those recurring issues (like that mysterious stoppage on Line 4) and find opportunities to get more out of the machines you already own.

And when you're ready, you can easily upgrade to the full FactoryIQ suite for scheduling, OEE, and more.

It's More Than Just Uptime, Too

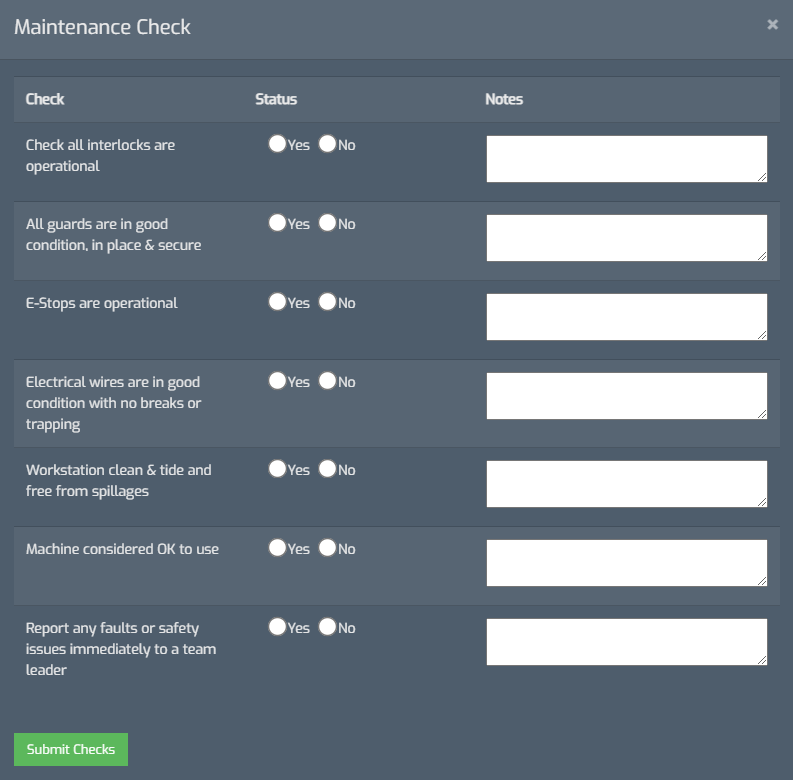

Compliance and safety are always on your mind. FactoryIQ can help there, too.

Our Maintenance Check feature lets you create custom daily checklists for each machine. It provides a complete historical record for compliance and a central place to flag issues. No more lost paperwork or pencil whipped forms. You can even set it up so a machine won't start a new job until its safety checks are passed. It's just one more way to have a single source of truth for everything that happens on the floor.

Stop Leaving Productivity on the Table

That gut feeling that you could be getting more out of your factory? It’s real. And you can prove it.

Book your free, 15 minute "Hidden Productivity" audit today.

We'll show you exactly how FactoryIQ can connect to one of your machines and uncover the real story of its uptime and downtime. We’ll help you find the hidden capacity you could unlock, almost immediately.

No pressure, no obligation. Just pure insight into your factory.