Advanced Production Scheduling

Beyond Spreadsheets. Beyond Guesswork: Take Control of Your Production Schedule and Your Productivity.

No IT Headache, No Massive Upfront Costs, Just Results

It’s 4:30 PM on a Friday. Of course it is.

A key machine just went down, and the operations manager has his most important client on the phone. He’s trying to explain a delay he doesn’t fully understand himself, staring at a whiteboard that looks like a crime scene of crossed out lines and frantic scribbles.

His best operator is standing by, waiting for instructions, but the paper job ticket for the next task is buried somewhere on a desk. The whole week’s schedule, so carefully planned on Monday, has completely fallen apart.

This isn’t just inefficient. It’s exhausting.

That feeling. That’s why we built FactoryIQ.

It’s for the moments when you wish you could just see everything. Clearly. In one place. When you need to know what’s really happening on your floor, not what you hoped would happen.

It’s about trading that gut wrenching chaos for quiet, predictable control. And to be honest, we think you’ve earned it.

Finally, a True Command Centre for Your Factory Floor

Let’s face it, most factory schedules are a mix of spreadsheets, whiteboards, and what I’d call ‘tribal knowledge’ locked in your best people’s heads. It sort of works. Until it doesn’t.

Our visual schedule isn't just another chart. It's a live, breathing view of your entire operation.

You can see a potential bottleneck forming hours before it grinds everything to a halt. You can run a quick simulation to see how a rush job will affect everything else. You can know, with certainty, if you're on track to meet every single deadline.

Imagine leaving work for the weekend knowing there won't be any nasty surprises waiting for you on Monday morning. That’s the feeling we deliver.

Think 'Going Digital' Means a Six-Month Headache?

We get it. The last thing you need is a massive, complicated IT project that costs a fortune and disrupts your entire workflow.

We built FactoryIQ for manufacturers, not for IT departments.

It’s designed to be simple. It works with the processes you already have, and it gives your team real time job lists on the tablets and phones they already use every day. This isn't about reinventing your factory. It’s about making it run the way you've always wished it would.

Your Factory, in Your Pocket

You’re not always at your desk. You’re on the floor, in a meeting with a supplier, or maybe even checking in from home. Your scheduling system should move with you.

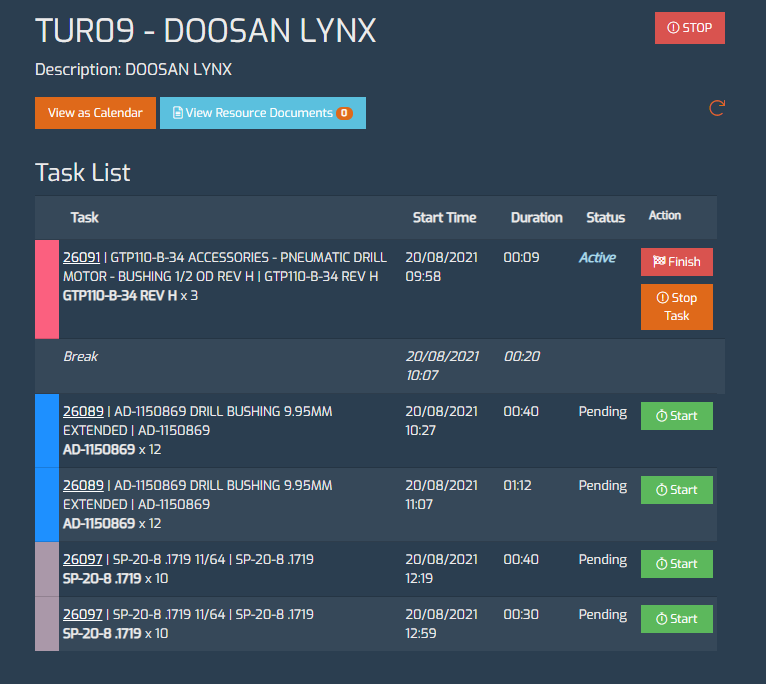

With FactoryIQ, your team has a crystal-clear job list right in their hands. They can start a task, pause it to log an issue (and the reason why), and record quantities and scrap the second a job is finished.

No more guesswork. No more shouting across the shop floor to figure out what’s next. Everyone is perfectly in sync, and you have a real time view of your entire operation, wherever you are.

Stop Throwing Profit in the Scrap Bin

Every piece of unnecessary scrap is cash you’re throwing away. Every minute of unexpected downtime is a hit to your bottom line. You know this, but it’s nearly impossible to see the patterns when you’re just trying to get orders out the door.

FactoryIQ tracks it all automatically.

Upon task completion, operators log the actuals and scrap. But the real magic is in the trends it reveals. Is one machine secretly less efficient? Is a specific shift consistently producing more waste?

Our system exposes these hidden profit leaks. It gives you the hard data you need to fix them for good, turning hidden costs back into revenue.

Ready to Swap Chaos for Calm Control?

A demo with us isn't a high pressure sales pitch. It's a conversation.

We'll listen to your specific challenges and show you exactly how FactoryIQ can solve them, usually in about 30 minutes. We’ll show you the visual schedule, the real time job lists, and the profit saving reports. You’ll see for yourself how it can bring a new level of clarity and control to your operations.